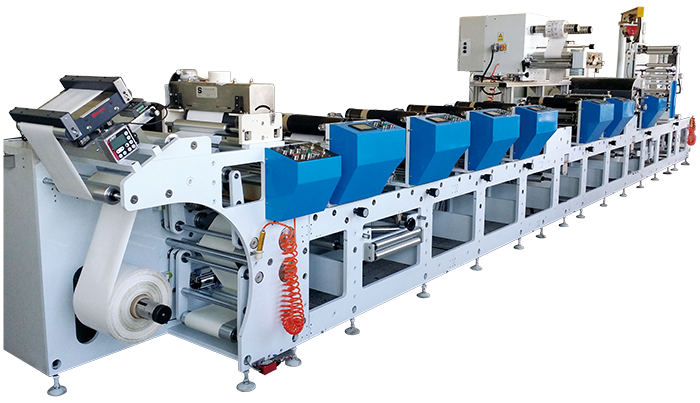

The Modular Full Rotary Flexo Printing Press

Features:

1. Unwind tension unit

- Standard: BST Web-guide device

- Separate servo-driven motor system

- Frictionless cylinder floating roller tension control technology

2. Flexo unit

- Three separate servo-driven motor systems

- Option: UV Curing unit or hot air unit.

- Equip with customized long drying oven

3. Die cutting and matrix unit

- Separate servo-driven motor system

- Option: Magnetic die cutter roller for precise die cutting

- Original invisible waste disposal technology to reduce losses caused by matrix process

4. Rewind tension unit

- Separate servo-driven motor system

- Equip with taper control high-precision rewind unit

Electricity control system

-Developed its own high-precision servo control system which can achieve precisely control of registration, rewind & unwind and synchronous

Options:

1. Cold foil unit with national patent

2. Slitting unit

3. Turn bar unit

4. Rails

Parameter

|

Max.Printing width |

350mm/420mm/520mm |

|

Color |

Customized |

|

Rewind/Unwind maximum diameter |

800mm |

|

Max.Working speed |

180m/min |

|

Accuracy of register image |

≤±0.12mm |

|

Accuracy of die cutting |

≤±0.15mm |

|

Printing perimeter |

250mm-520mm |

|

Power |

According to machine's configuration |

|

Dimension |

According to machine's configuration |

|

Weight |

According to machine's configuration |

All technical data are approximate.